Getting The Injection Mold To Work

Wiki Article

Injection Mold Fundamentals Explained

Table of ContentsThe Injection Mold Ideas9 Easy Facts About Injection Mold DescribedThe 30-Second Trick For Injection MoldTop Guidelines Of Injection MoldThe Only Guide for Injection MoldWhat Does Injection Mold Mean?10 Simple Techniques For Injection Mold

Because of this, the plastic within the moulds is pressed harder and also enables a large amount of information to be imprinted onto the component and for facility or intricate shapes to be made. Countless components can be created prior to the tooling needs to be maintained. There is a big selection of polymer materials to select from.

This is a substantial benefit when trying to produce high resistances and also part reliability in high quantities. Injection Mold. There is often really little post-production job required as parts typically have a good completed appearance upon ejection. When plastic injection moulding, it is possible to utilize fillers in the moulding material. These fillers decrease the thickness of the plastic whilst it is being molded, and can help add greater toughness to the finished part.

The Buzz on Injection Mold

There is the initial style and prototyping (most likely by means of CNC or 3D printing), after that the design of a prototype mould tool to generate replicas of the part in volume. And only after extensive screening throughout both phases, you can ultimately shot mould a part. Plastic components must be developed with shot moulding factor to consider as well as should adhere to the basic rules of injection moulding, for instance: Avoid under cuts and sharp edges as high as feasible Usage attire wall surface densities to prevent disparities in the cooling process resulting in problems like sink marks.

Don't neglect, due to the fact that devices are commonly made from steel or aluminium, it can be difficult to make layout changes. If you need to include plastic to the component, you can make the device tooth cavity larger by reducing away steel or aluminium. In order to take away plastic, you need to decrease the dimension of the device cavity by adding aluminium or steel to it.

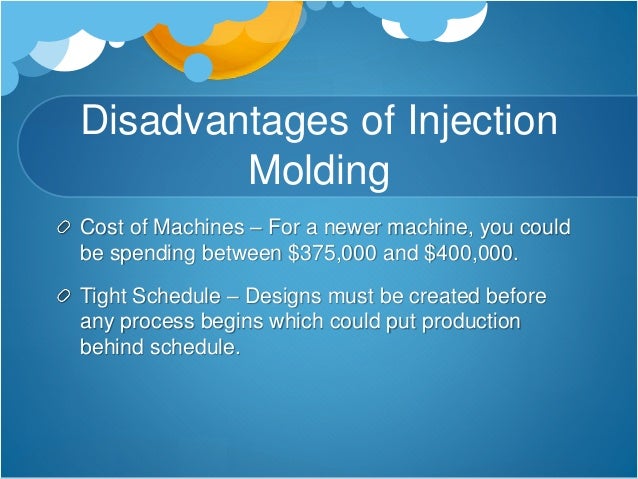

Additionally, the weight as well as size of the part will certainly figure out the tool size and also needed press size. The larger the component, the harder and pricey it will be. Due to the intricacy of tooling, and also the requirement to rid the equipment of all previous material prior to the following product can be made, the configuration time can be rather lengthy.

The 15-Second Trick For Injection Mold

Shot moulding is a terrific process! The variety of materials as well as colours is big, as well as there is no "abdominal muscles like' that we obtain in 3D Printing, it's the real point. Components are repeatable and tight resistance. The only possible disadvantage is the tooling, but as we stated at the start of this article, we've got that covered, with choices to match most requirements.Thick sections can cause various issues, including warping and sinking. Limiting the maximum density of any section of your design to the recommended values by is essential. To boost the stamina of hollow area, to create structures of equal stamina and rigidity however reduced wall density. A properly designed part with hollow areas is shown listed below: Hollow thick sections as well as add ribs to boost stiffness Ribs can likewise be used to enhance the stiffness of without boosting their thickness.

Surpassing the recommended rib density (see listed below) can lead to sink marks. The wall thickness limitations still use for ribs Burrow thick sections and also utilize ribs to enhance the strength and also tightness of the part Layout ribs with max. thickness equal to 0. 5x the wall surface thickness Design ribs with max.

About Injection Mold

This will likewise aid to decrease the price of your medical gadgets. All shot molding tasks, including medical ones, first begin with a shot molding tool as well as pass away. To make a complex shape could require making a similarly intricate their website mold tool, so there is a first product style and also growth investment that needs to be taken into consideration before a single medical gadget is made.

Actually, bigger production volumes tend to redeem the tooling price gradually due to lower price-per-part. That's why injection molding is ideal for instead generic gadgets like containers, tubes, or disposable single-use medical products like syringes. Shot molding supplies options for every one of your medical device needs. Shot molding is specifically beneficial when making instances and also rooms.

However those other manufacturing techniques would be much slower, consume even more resources, and would certainly lead to a fairly high manufacturing price per part. That is why a various manufacturing procedure would make feeling only for low-volume or customized work when you don't desire to purchase a tool. Clinical device shot molding has a faster manufacturing time, and also a lower price per component, and makes use of medical-grade plastics that make it optimal for cases as well as enclosures.

6 Simple Techniques For Injection Mold

Some are just simple elements like device holding trays, tablet dispensers, or real estates for sensors. Big plastic real estates are especially helpful for innovative medical equipment - Injection Mold. Not only is plastic lightweight, sturdy, and more economical than alternate products, yet it additionally will not conflict with electromagnetic energy such as would be used in feline scans, MRIs, as well as X-rays.There are hundreds of plastic materials to select from for manufacturing that is easily available on the commercial market. As well as thankfully a number of these materials are ideal for medical devices. These materials have mechanical and Look At This chemical homes which are well recognized so it's very easy to select the one that's most proper for its end usage as well as atmosphere.

This will certainly likewise help to lower the cost of your medical devices. To make an intricate shape might call for making a similarly intricate mold and mildew tool, so there is a first item design and also advancement financial investment that needs to be taken into consideration before a single clinical linked here device is made.

Injection Mold - The Facts

In fact, bigger manufacturing volumes often tend to recoup the tooling price in time due to the fact that of lower price-per-part. That's why injection molding is excellent for rather generic gadgets like containers, tubes, or non reusable single-use medical products like syringes. Shot molding offers services for every one of your clinical device requirements. Injection molding is specifically helpful when producing instances and also enclosures.Those other production methods would be much slower, take in even more raw products, and also would certainly result in a reasonably high production expense per component. That is why a various manufacturing procedure would certainly make good sense just for low-volume or personalized jobs when you don't desire to purchase a tool. Medical device shot molding has a much faster manufacturing time, and also a lower cost per component, and also makes use of medical-grade plastics that make it ideal for instances and also units.

Some are simply basic parts like device holding trays, pill dispensers, or housings for sensing units. Huge plastic housings are specifically helpful for innovative medical tools. Not just is plastic light-weight, sturdy, and also less costly than different materials, yet it likewise will not interfere with electro-magnetic power such as would be used in pet cat scans, MRIs, and also X-rays.

The Best Guide To Injection Mold

There are thousands of plastic materials to select from for making that is easily readily available on the commercial market. And also fortunately a number of these materials are suitable for clinical devices. These resins have mechanical and also chemical properties which are well recognized so it's simple to choose the one that's most proper for its end usage as well as environment.Report this wiki page